QuadLN_S Firmware

QuadLN_S Version 3.3 Update Package

Current production QuadLN_S Version 3.3.2 firmware including manuals covering V3 features for all QuadLN_S family products. Version 3 has the most recently added features including support for up to 16 servos or stall motors, servo refresh, aspect-controlled turnouts, oscillate mode, center-align, etc. See the included ReadMe file for more info. (If you are running JMRI 5.8 support is built-in so the JMRI update steps can be skipped)

QuadLN_S Version 3.2 Update Package

QuadLN_S Version 3.2.4 firmware including manuals. Version 3.2.4 is very stable. See the included ReadMe file for more info.

QuadLN_S Version 2.0.7 Update Package

QuadLN_S Version 2.0.7 firmware including manuals covering V2 features for all QuadLN_S family products. See the included ReadMe file for more info.

JMRI

JMRI Update Package for QuadLN_S Version 3.3

JMRI version 5.7.7 contains the latest QuadLN_S decoder files. If you cannot update to JMRI version 5.7.7 or later, this package has updated decoder files for JMRI v5.2-v5.7.6 that support the latest features in the QuadLN_S Version 3.2 firmware. (If you are running a JMRI version prior to 5.2 then you must update to at least V5.2 to use this update file.)

If you are already running JMRI version 5.7.7 or later and you previously installed any QuadLN_S decoder files in the decoders folder or xml\decoders\tvd folder within your Users Files Location, you should delete those files.

JMRI Update Package for QuadLN_S Version 3.2

JMRI version 5.2 contains the latest QuadLN_S decoder files. If you cannot update to JMRI version 5.2, this package has updated decoder files for JMRI v4.26 -v5.1.7 that support the latest features in the QuadLN_S Version 3.2 firmware.

Note: If you are already running JMRI version 5.2 and you previously installed any QuadLN_S decoder files in the decoders folder or xml\decoders\tvd folder within your Users Files Location, you should delete those files.

Manuals

QuadLN_S Getting Started Guide

QuadLN_S Manual Version 3 Firmware

QuadLN_S Manual Version 2 Firmware

Remote Align Board Quick Start

Instruction Sheets

Pushbutton with LED Ring Light

Signal Connector Interface Board

Linear Switch Machine Throw Wire Changeout

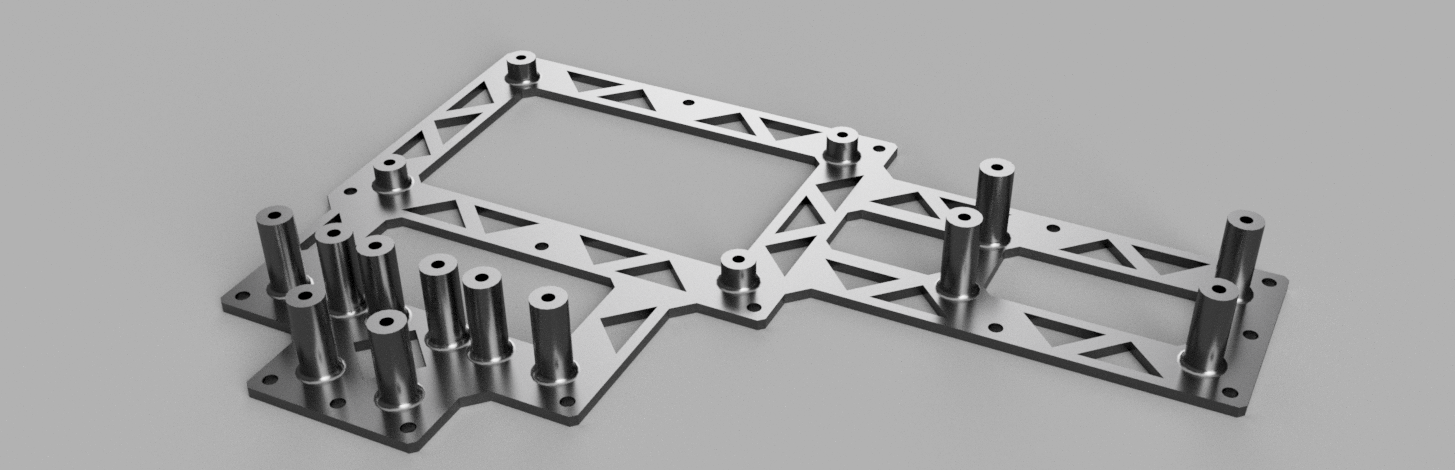

Mounting Plate

QuadLN_S Mounting Plate stl file (c) 2022 N3IX Engineering

A QuadLN_S mounting plate design for 3D printing. The mounting plate has built-in standoffs for a QuadLN_S and any combination of Detector, Signaling and Driver add-on boards. Use 1/4″ or 3/8″ long #4 self-tapping screws to secure the boards to the mounting plate, then attach the mounting plate to a flat surface using appropriate length #4 screws as required.

I typically print the mounting plates using PLA with 25% infill. Printing takes about 3 hours on my Vyper. The board mounting hole size has been tweaked to make it easy for me to start #4 screws without pre-drilling. Depending on your printer and filament you may need to clean out the holes using a 3/16″ or 7/32″ bit, or alternatively use a small amount of “Hole Horizontal Expansion” in your slicer, to make threading the screws easier and lessen the risk of breaking a standoff.

If you aren’t installing a Driver Board in the AUX IO Port, you can just snip off the standoff closest to the Remote Align Connector to make access to the connector easier.

QuadLN_S Mounting Plate for TVD boards stl file (c) 2022 N3IX Engineering

The QuadLN_S mounting plate design as above, but adjusted for the board sizes and hole locations of the legacy QuadLN_S, Signal and Detector boards that were produced by Tam Valley Depot.

Drill Guides

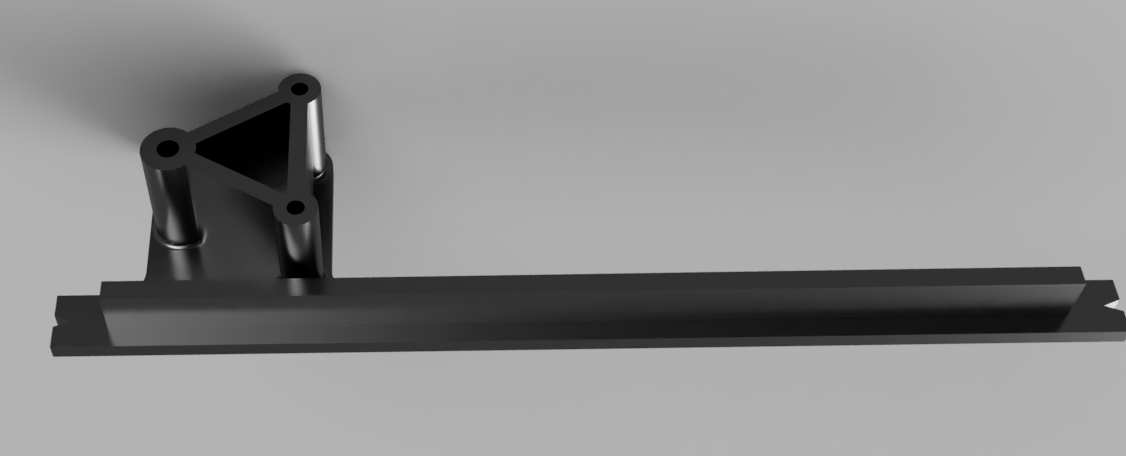

3-D Printed N Scale Atlas Code 55 Drill Guides and more

Drill templates you can print for use with the Linear Switch Machines and Atlas Code 55 N Scale Turnouts. To download the printer files click the link to go to my layout 3D Printing page.

Tips and App Notes

Yard Track Selection Via Single Button Press For 6 Track Yard

Guide to configuring the Cascade feature for easy alignment of a 6 track yard ladder to the desired yard body track via a single button press. Also covers setting up LED indicators to display the currently selected yard body track. All done using just one QuadLN_S.

Yard Track Selection Via Single Button Press For 10 Track Yard

Guide to configuring the Cascade feature for easy alignment of a 10 track yard ladder to the desired yard body track via a single button press. Also covers setting up LED indicators to display the currently selected yard body track. Uses 2 QuadLN_S boards (some of the second board is available for other uses) plus a Signal Board.

Example JMRI Jython Script to Interrogate QuadLN_S boards one at a time

At startup JMRI attempts to determine the state of all LocoNet Turnouts and Sensors using a process called Stationary Interrogation. On large layouts many LocoNet devices may respond to each Interrogation message, resulting in message collisions, long delays and possible lost information. QuadLN_S firmware version 3.1.4 and later can be configured to support direct interrogation, where only one QuadLN_S board responds to each status request. This approach provides for reliable initialization on large layouts. The sample script individually interrogates all QuadLN_S boards in the roster between a specified starting board address and a specified ending board address.

DigiKeijs DR5000 settings for reliable LocoNet communication

Settings that users have found improves the DR5000 communications with the QuadLN_S and other LocoNet devices.

User Support Groups

Tam-Valley-Products@groups.io is the forum for QuadLN_S questions and discussion.

jmriusers@groups.io is the place for all things JMRI.