Servo Motor Control

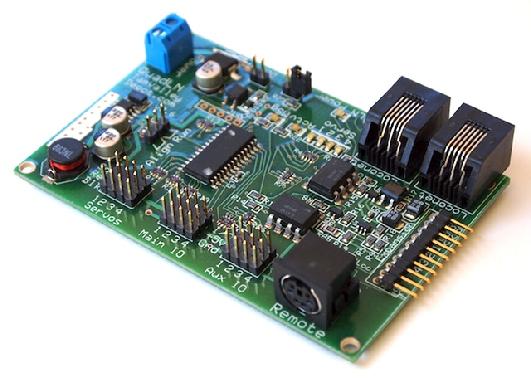

Designed and developed software for an innovative rc servo motor controller. This low cost device is based on a PIC microcontroller and handles 4 servos, has 8 general purpose I/O lines and fully supports the popular LocoNet® CSMA/CD network. The design allows easy software field upgrades. Wrote user manual and provide on-going support to customer base.

Air Quality Monitoring

Led development of the next generation product line at the leading manufacturer of air quality monitoring instrumentation. The new product line features a rugged, modern appearance, color graphics display with touch screen interface, ethernet and usb ports and runs under WinCE. Conceived and implemented the full-featured yet straightforward onboard and remote user interfaces.

Fuel Control Valves and Actuators

Relentlessly drove product development, innovation and quality improvement on a leading family of fast, stable and accurate fuel values and high force actuators for industrial gas turbine and reciprocating engines. Digital control using TI DSP and Freescale embedded processors.

Safety and Critical Control

Restructured and aligned the product development organization at the industry leader for fault tolerant controllers. The best-in-class systems employ a ruggedized, triple-modular-redundant architecture and are used worldwide in applications where safety, reliability and availability are tantamount.

Web Inspection and Machine Vision

Spearheaded development of a high-performance, linescan web inspection system that provides realtime inspection of continuously manfactured materials. Custom linescan cameras employ a high-speed hardware image processing pipeline teamed with image analysis software running on a Motorola PowerPC under VxWorks. This hardware/software combination provides fast, accurate defect detection, enabling complete, realtime surface inspection even in the most complex textiles, plastics, papers, films and non-woven materials. Responsible for all aspects of development including concept, design, test, sales, marketing, field service and customer support.

Nuclear Power Plant Radiation Monitoring

Led product development at the premier supplier of radiation monitoring systems for nuclear power plants. The current, highly advanced system utilizes an Intel 80960 along with multiple Intel 8051 processors to set new standards for versatility, maintainability, and cost-efficiency.

Rotating Machinery Monitoring

Developed advanced condition monitoring systems for rotating machinery. The online system for API-670 compliant machinery protection used a Motorola 68000 along with multiple 68HC11 processors to provide flexibility, reliability and value. Portable instruments for predictive maintenance used NEC V series and Motorola processors.

Instrumentation for Turbines, Diesels, and Heavy Equipment

Performed a wide range of design projects including the first color LCD operator display for heavy equipment and a real-time control system for a supersonic steam turbine. Implemented a Motorola 68000-based data acquisition system for an on-highway truck engine that allowed rapid diagnosis and correction of an engine problem experienced by a major customer that had been extremely elusive.

Groundbreaking Gas Monitors

Developed hand-held instruments for anesthesiology, respiratory therapy, and industrial applications. A major highlight was the design and introduction of the first microprocessor-based oxygen monitor. Based on a Motorola 6805, the monitor featured adaptive filtering, long battery life, and the first use of fault tolerance techniques developed at Johns Hopkins University. Also developed a microprocessor-based, portable carbon monoxide monitor for industrial safety applications.